- 🏆 Exclusive

- 🌟 New release

Timor-Leste Atsabe Natural Nº 257

Tastes Like:

Apricot, Orange, Summer Fruit Cordial

Roast:

This rural coffee growing community in Atsabe, Timor-Leste, produces both washed and natural styles. Therefore tasting both is the perfect way to see how Read more

About Timor-Leste Atsabe Natural Nº 257

This rural coffee growing community in Atsabe, Timor-Leste, produces both washed and natural styles.

Therefore tasting both is the perfect way to see how processing techniques impact flavour and this natural version couldn’t be more different than the more classic washed - with floral aromatics and syrupy sweet fruit notes.

- Free delivery on orders over £25

- Roasted fresh to every order 🔥

- Dispatched next working day 📆

- 100% recyclable packaging 🟢

Delivery information

Roasted & dispatched the next working day with Royal Mail Tracked service.

Order Value

£0.00 - £9.00 = £2.95

£9.01 - £20.00 = £3.75

£20.01 - £24.99 = £3.95

£25+ = Free UK Shipping

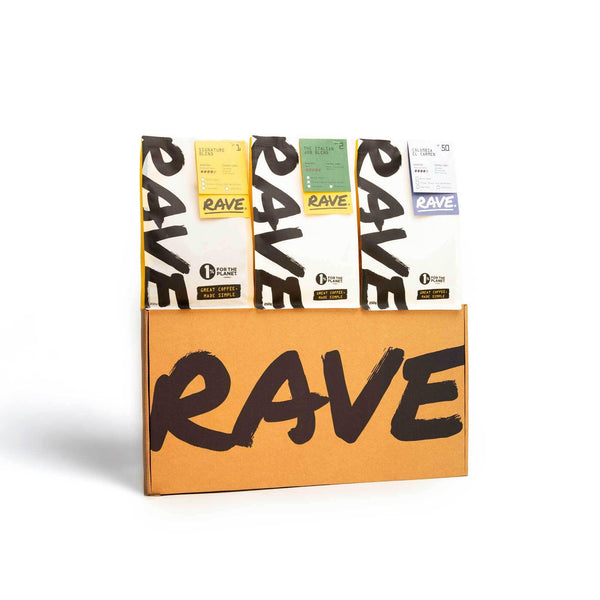

Join our coffee club

And get the newest coffees delivered straight to you every month!

How our subscribe & save works;

You have complete control...

Change products, delivery dates or cancel with the click of a button.

No unexpected deliveries or charges...

We'll send you an e-mail before every delivery in case you want to change anything.

10% off all orders...

We’ll reward your commitment to great coffee with a 10% discount on every order.

Timor-Leste

Natural

Smallholders

Atsabe, Ermera

1400m-1600m

Hibrido de Timor, Moka, Typica

The region is remote and the altitudes difficult to scale. But the building of more washing stations in recent years has enabled more speciality coffee to be produced, where the process of cherry pulping, fermenting and drying can be carefully controlled to ensure the best coffees are prepared for export.

Any coffee that doesn't fulfil strict criteria for speciality is separated and sold to local markets - nothing goes to waste.

This natural processed lot is comprised of hand-sorted coffee cherries that are left to dry on high raised beds for one month. They need to be regularly turned for good airflow and even drying. Once the cherries have reached a 14% moisture content, they are transported to lower altitudes (higher temperatures) for the final drying phase. The removed cherry fruit and skins are repurposed for fertilizer and the coffee beans begin their journey to shipment.

Ash says...

Try this coffee side by side with the Atsabe washed - a rare opportunity to taste processing at work!

Best-Sellers

best selling Coffee

We’re a member of 1% For The Planet. So, whether we make a profit or not, we will donate 1% of all sales to environmental causes. That's coffee with a conscience.